Cabina de esterilización Solución flexible para fábricas inteligentes

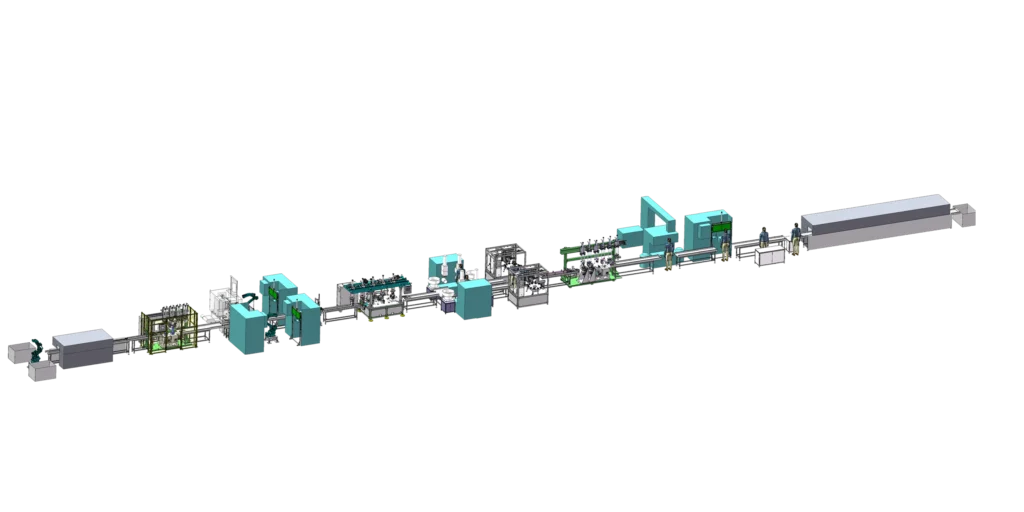

Hemos desarrollado con éxito una línea de producción de estampación y montaje flexible totalmente automatizada y adaptada para la personalización a gran escala de armarios de desinfección.