Robot d'estampage

Effectively addresses the efficiency bottlenecks and safety hazards associated with manual operations, achieving dual improvements in both production efficiency and yield rates.

- Precision

- Durability

- Synchronization

Industrial Stamping Press Robots: Tailored to Elevate Production

As a pioneering manufacturer of industrial automation solutions, we specialize in delivering state-of-the-art press robots engineered for peak performance in precision manufacturing. With advanced motion control and seamless system integration, our solutions elevate productivity, deliver unparalleled accuracy, and drive production excellence across the automotive, electronics, and metalworking sectors. Trusted by global industries, we redefine reliability in high-speed stamping automation.

Feature of Product

Designed to redefine manufacturing excellence, our robotic stamping provides unwavering precision and reliability with every stamping cycle.

Servo Drive

AC servo actuation across axes includes traverse, lift, and grip, and is synchronised with encoders to ensure stamping precision.

Synchronization Mechanism

Connected to the stamping crankshaft via an encoder, ensuring complete synchronisation with the press.

Versatile Material Handling

Supports coil (air/NC servo feeders) and sheet (dual-station rack) feeding, ensuring adaptive production flexibility for any stamping task.

Precision Control

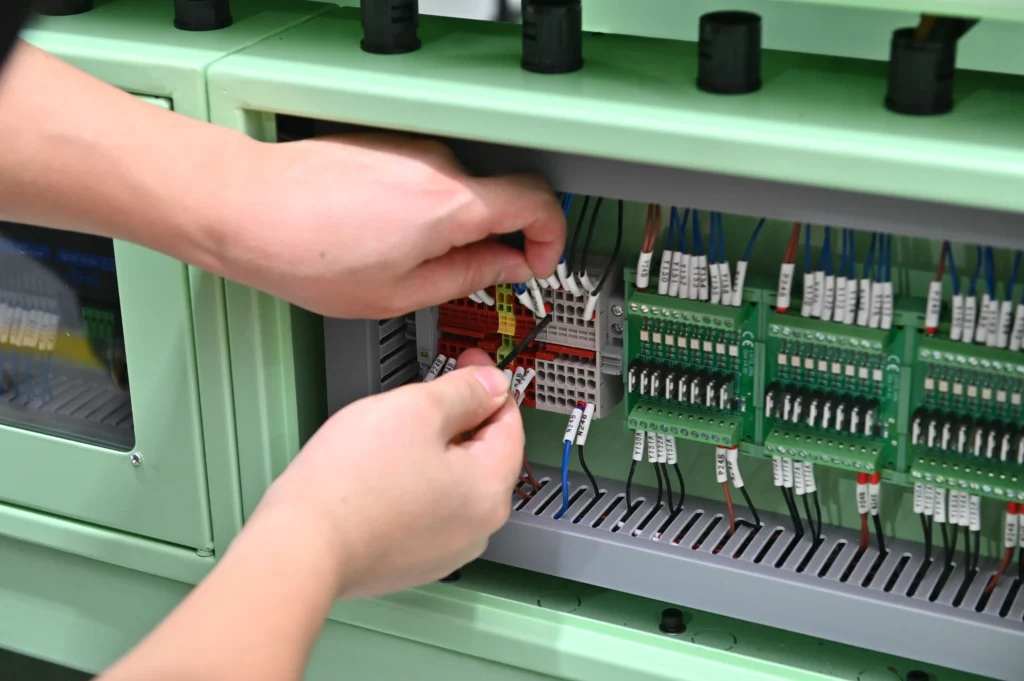

The ability of a press robot goes beyond its mechanics to encompass its control architecture. By combining robust computing with operator-centric design, we create a command ecosystem that maximises precision and responsiveness.

- High-performance PLC with touchscreen HMI

- EtherCAT bus control is supported by certain models

- Fiber optic communication is supported by certain models

Adsorption Methods

In modern manufacturing, the diversity of materials demands adaptive solutions. Our stamping robots provide multi-mode adsorption systems that are engineered to handle metals, plastics, and composites with identical precision.

- Vacuum Suction

- Electromagnetic

- Permanent Magnet

Intelligent & Extensible

In an era of smart manufacturing, our stamping robots redefine operational intelligence. We create a self-monitoring ecosystem that reduces downtime. From predictive maintenance to plug-and-play reconfiguration, our stamping systems embody Industry 4.0 principles.

IoT Integration

Real-time equipment monitoring and predictive maintenance.

Smart Maintenance

Fault alerts and remote diagnostics (mobile app optional)

Drag-Teaching

Simplifies programming for non-experts

Energy Efficiency

Our mechanical arms can achieve energy savings of up to 30% compared to conventional pneumatic systems thanks to their integrated regenerative braking and servo-optimised motion control. Their modular architecture simplifies upgrades and maintenance, minimising operational disruption and extending equipment lifespan thanks to replaceable components.

- Reduce energy consumption

- Extend lifespan

Industry Compatibility

We provide vertically integrated solutions engineered to resolve industry-specific operational challenges, combining proprietary algorithms, modular hardware architectures, and process optimisation frameworks that are tailored to the manufacturing demands of different industries, include automotive, home appliances, and home hardware.

Contactez-nous pour commencer votre voyage vers la la fabrication intelligente

Notre équipe d'assistance technique vous apporte une aide rapide et personnalisée afin de garantir le bon déroulement de vos opérations.