Стерилизационный шкаф Гибкое решение для умной фабрики

Мы успешно разработали полностью автоматизированную гибкую линию штамповки и сборки, предназначенную для крупномасштабного индивидуального производства дезинфекционных шкафов.

The washing machine cabinet, with its maximum height exceeding 1.5 meters and weight reaching up to 20 kilograms, is typically produced through a four-step process involving a 400-ton heavy-duty press machine in conjunction with molds. This traditional manufacturing process presents two major pain points. Firstly, since the washing machine models are differentiated based on cabinet size, each model necessitates a unique set of molds, thereby escalating costs, occupying valuable production space, and causing significant inconvenience during mold changes on the production line. Secondly, the large spacing of 6 meters between consecutive heavy-duty press machines, coupled with the cumbersome size and weight of the cabinet sheet metal, necessitates a total workforce of 20 individuals per line, resulting in extremely low efficiency and frequent workplace injuries. This has become a quintessential labor-intensive production line.

The traditional process relies on two sets of molds, with manual mold changes and material feeding to produce two different specifications of components. This approach entails increased mold costs, space utilization, time-consuming efforts, high accident rates, and inefficiencies.

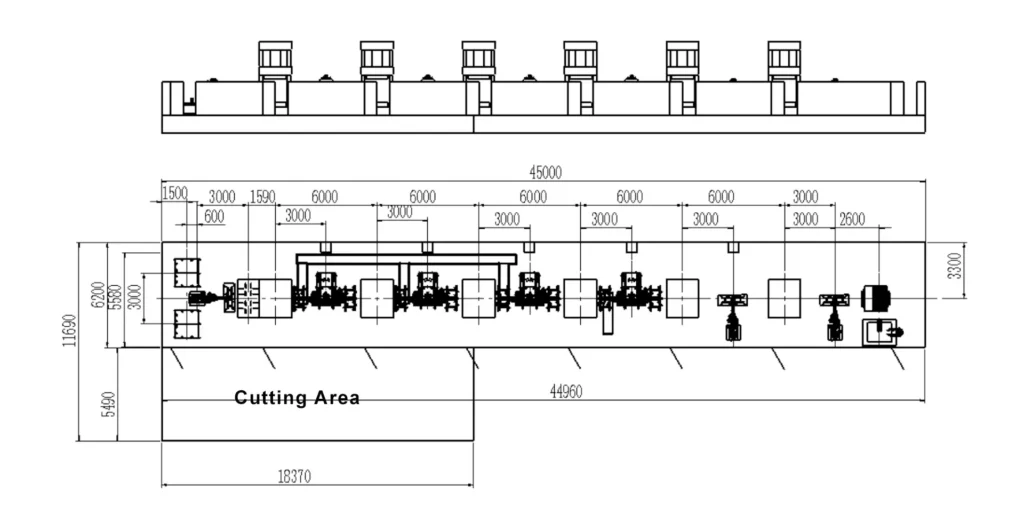

The solution includes integrating one secondary positioning station, four independent stamping robotic arms, three articulated robots, seven waste material conveyor belts, two product conveyor belts, one riveting mold with feeding device (excluding the hydraulic press), and two single-station sheet metal feeders. This setup facilitates a fully automated production workflow, encompassing automatic feeding of raw materials for washing machine cabinets, stretching, stamping, waste collection (including scraps), riveting, and stacking.

We have autonomously developed a simple and rational mold design that meets the needs of producing two different specifications of components with a single mold, addressing an industry gap and aligning with energy conservation and emission reduction objectives. This mold leverages PLC-controlled cylinders for mold changing, ensuring intelligence and environmental friendliness. In practical applications, it seamlessly integrates with independent robot hardware and software, achieving a high level of intelligence and automation.

This production line is suited for large sheet metal components, offering extensive grasping capabilities and multi-directional rapid flexible production, including left-right, up-down, and turning movements. It can replace imported robots, reducing costs by 50% and increasing efficiency by 60%.

It offers absolute advantages in terms of quality and safety, eliminating concerns related to product quality, workplace accidents, and employee management.

| Перед обновлением | После обновления | Notes | |

| People | Workforce: 20 people/shift * 3 shifts/day = 60 people/year Annual salary: 60 people * $5,000/month* 12 months = $360 million Annual production: 6 pcs/mins * 60 minutes/hr * 24 hrs/day * 365 days/year ≈ 315 million pcs | Workforce: 1 person/shift * 3 shifts/day = 3 people/year Annual salary: 3 people * $5,000 /month * 12 months = $18 million Annual production: 12 pcs/mins * 60 mins/hour * 24 hrs/day * 365 days/year ≈ 630 million pcs | Labor cost reduced by 20 times Annual production increased by 2 times |

| Machines | Regular use of one forklift (with a driver) Press machine utilization rate: 70% | Press machine utilization rate: 95% | Utilization rate increased by 36% Mold cost reduced by 2 times |

| Materials (Molds) | 2 sets * 5 processes = 10 molds Cost: ¥300 million | 1 set * 5 processes = 5 molds Cost: ¥150 million | |

| Methods | Necessitates attendance, performance, safety precautions, and other regulatory frameworks | Requires only machine maintenance | Automation, intelligence, informatization, and lean management |

| Окружающая среда | Crowded workforce, space occupied by molds, forklift traffic, messy and unsafe conditions | Workshop resembles an exhibition hall |

Мы успешно разработали полностью автоматизированную гибкую линию штамповки и сборки, предназначенную для крупномасштабного индивидуального производства дезинфекционных шкафов.

Используя всю промышленную экосистему нашей компании, мы создали высокоинтеллектуальную, автоматизированную и гибкую производственную линию.

В рамках этого проекта реализуются высокоавтоматизированные и гибкие производственные процессы для термического монтажа статоров и корпусов компрессоров, прессовой сборки роторов и корпусов насосов, а также онлайн-контроля при сборке насосов.

Мы предлагаем оптимальную автоматизацию пресс-форм или различные методы интеграции роботов, адаптированные к различным процессам и процедурам изготовления пресс-форм для интеллектуальной штамповки компонентов наружного блока кондиционера, таких как левая и правая боковые панели, крышки, верхние крышки, передние панели и электрические крышки.

Компания Kaishuo Technology была основана в 2008 году и с тех пор создала четырехъядерную промышленную структуру, включающую робототехнику и оборудование для автоматизации, новые источники энергии, прецизионные аппаратные формы и прецизионные литьевые формы.

Copyright © 2025 Kaishuo Technology